$ 0.006 -0.54%

Beam (BEAM) Rank 206

| Mkt.Cap | $ 352.62 M | Volume 24H | 392.33 MBEAM |

| Market share | 0% | Total Supply | 262.8 MBEAM |

| Proof type | PoW | Open | $ 0.0060 |

| Low | $ 0.0059 | High | $ 0.0061 |

ELI5: Why do engineers use I-beams when the triangle is the strongest shape. : explainlikeimfive

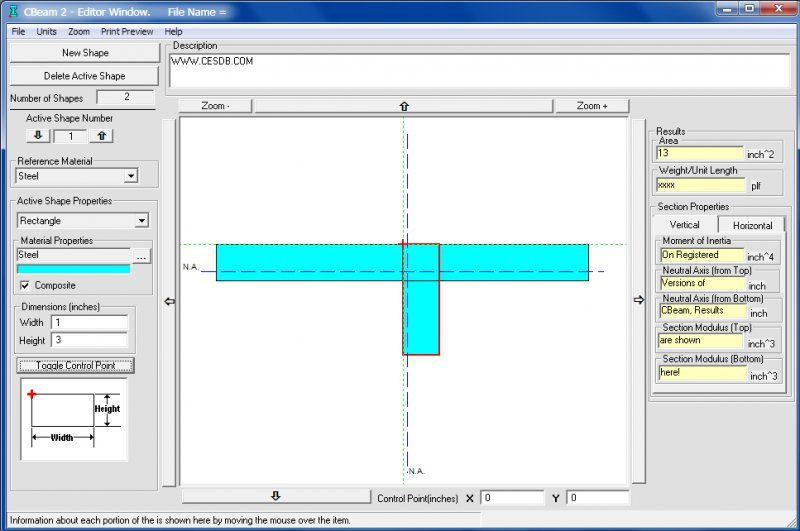

What is an I-Beam?

The I beam consists of two horizontal planes, known as flanges, connected by one vertical component, or the web. I-beam hastapered edgesand it gets its name from the fact that it looks like acapital Iwhen you see it from its cross section. With an I-beam, the height of the cross section is higher than the width of its flange.

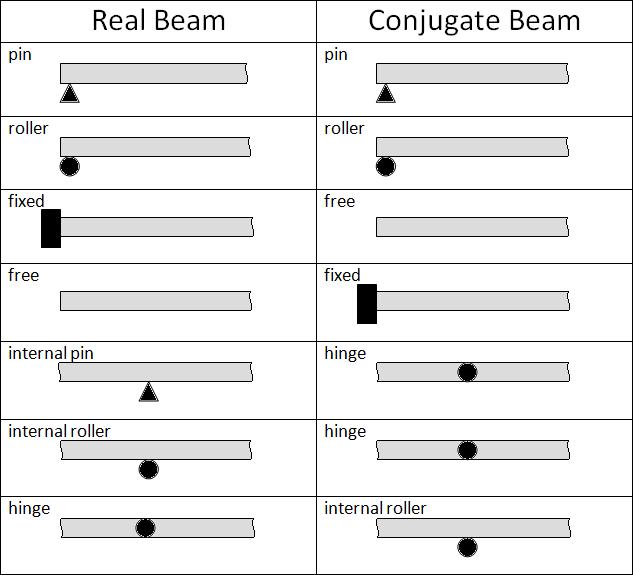

In the world of structures there are two basic families of members--flexural and axial. Members that resist flexure are known as beams and members that resist axial are split up into categories depending on whether or not they are under compression or tension (cables, columns, rods, etc).

Rod ratio is the length of a connecting rod (center to center) divided by the stroke of the crankshaft. This number can have a direct effect on power, torque, engine efficiency, and piston wear. This can be thought of as an extension of the heat-treatment process.

Tampa Steel & Supply

Understanding the I-beam is a basic necessity for the modern civil engineer or construction worker. Engineers use I-beams widely in construction, forming columns and beams of many different lengths, sizes, and specifications. With some buildings where weight and force on a wall may pose a structural issue, the I-beam may be better since it is often lighter. The designation of the wide flange I beam gives information about the width and weight per unit length. For example W12 X 96 means 12 inches depth and 96 pounds per foot weight per unit length.

What is continuous beam in civil engineering?

The definition of beam is a piece of wood, metal or steel which is typically long and squared that can be used as a building material. Beam is defined as a column of light, or a condensed flowing of particles, waves, or signals. An example of a beam is the illumination produced from a lighthouse.

OTHER WORDS FROM beam

I-beams are the choice shape for structural steel builds because the I-beam makes it uniquely capable of handling a variety of loads. The shape of I-beams makes them excellent for unidirectional bending parallel to the web. The horizontal flanges resist the bending movement, while the web resists the shear stress.

Mainly beam carries vertical gravitational forces, but can also pull the horizontal loads on it. Beam is called as a sill plate or wall plate that carries the load and transmits it to the girders, walls or columns it is attached with.

1. Simply Supported Beam:

The pointed section would crumple (or stretch, depends which way up) and the beam would fail. I-beams are intended to span between columns, so they specifically need to be optimised to handle bending. When a beam (any beam) is loaded, it bends in the middle, and its internal stress varies between max tension at the bottom and max compression at the top. If the webbing is overstressed, it gives a little and transfers the stress to the top or bottom anyway.

By choosing the right connecting rod material, size, and style (and don’t forget the right bolts, too), you’ll ensure maximum performance and reliability from your engine. You’ll also want to make sure the rods have been heat-treated, which is required for a material to meet most SAE/ASTM specifications. Shot peening is common and an absolute must for machined or forged parts, according to Davis. Polishing helps reduce microscopic pits, inclusions, and lead to extended fatigue life; however, it must be done properly. Aggressive grinding or polishing can actually do more harm than good.

Stock V8 connecting rods can handle upward of 400 horsepower and 6,500 rpm. Once you exceed those performance levels, you’ll need to consider aftermarket connecting rods. Depending on the type of steel used (we’ll get more into that below), aftermarket I-beams can handle hefty compressive loads, offer good tensile strength, and are often more lightweight than H-beams. Internally, beams subjected to loads that do not induce torsion or axial loading experience compressive, tensile and shear stresses as a result of the loads applied to them. Above the supports, the beam is exposed to shear stress.

Dynamometer: Introduction and Types

The immense power of I beams reduces the need to include numerous support structures, saving time and money, as well as making the structure more stable. The versatility and dependability of I-beams make them a coveted resource to every builder. It gets its name because it looks like a capital H over its cross section.

Related Posts on Strength of Materials topic(s)

The lighter weight reduces the overall mass of the reciprocating assembly, allowing the engine to rev faster and higher. According to Davis, aluminum is also a great choice for supercharged applications. Whether you choose H-beam or I-beam, overall strength and reliability is dependent upon the material, weight, and cross-section of the rods, said Nick Norris of Callies Performance Products. Depending on the application, different types of stresses are applied to the connecting rods. For example, large amounts of torque will yield heavy compression and bending loads on the rods.

- Again, the right choice for you will depend on the variables (power, rpm, application, etc.) above.

- Primarily used in the frames of manufactured homes and recreational vehicles (RVs), this product is also utilized in purling applications and for steel dunnage.

- Also using a triangle, the beam would be less likely to twist.

- With some buildings where weight and force on a wall may pose a structural issue, the I-beam may be better since it is often lighter.

- Triangles are strong indeed, but you're considering the wrong plane for the stress.

Beams are characterized by their manner of support, profile (shape of cross-section), equilibrium conditions, length, and their material. Titanium connecting rods combine the lighter weight of aluminum with strength that’s more comparable to steel. That makes them a viable option for drag cars or sprint cars that require quick throttle response. Beam is a structural element which withstands against the bending.

What is simple beam?

Definition of simple beam. : a structural beam that rests on a support at each end.

If you’re a racer and can afford to change out rods more frequently, aluminum is a good choice. If you’re on a budget or if your engine is a high-torque, low-rpm mill, steel may be a more cost-effective option in the long run. When it comes to connecting rods, the main material options are steel, aluminum, and titanium.

Wide flange I beams are most commonly used structural steel shape in construction works. Materials of wide flange beams are generally structural steels such as A36, A572, A588 and A992.

The most commonly occurring axial loaded member in structural engineering is a compression member, called a column. Tensile rods and cables are common in bridges but rare elsewhere. So many members in structural design act as either a beam, a column, or a hybrid beam-column.

The primary tool for structural analysis of beams is the Euler–Bernoulli beam equation. This equation accurately describes the elastic behaviour of slender beams where the cross sectional dimensions are small compared to the length of the beam.

Most aftermarket steel connecting rods are made from forged steel. That’s why we turned to the experts at Eagle Specialties, Lunati, and Callies Performancefor tips on how to choose the right connecting rods for your engine and application. Not surprisingly, horsepower and torque are major factors in the equation. According to Alan Davis of Eagle Specialties, it’s not just about overall power and torque levels, but also the way power is made.

There are different types of forged steel based on the grade of material. Eagle Specialties, for example, uses a 5140 steel for its entry-level rods. For more highly modified competition applications, most manufacturers, including Eagle Specialties, utilize high-carbon 4340 or 4330 steel.

If you were to put a point load in the middle of a beam, intuition seems as if the triangle shaped beam would be able to withstand much more weight. Also using a triangle, the beam would be less likely to twist. The I-beam I feel has a greater potential for it to sort of collapse on itself due to welds, material imperfections, etc.

What is beam and its type?

Miscellaneous (M) Beams. Miscellaneous (M) Beams provide an exceptional low weight-per-foot hot rolled solution. Primarily used in the frames of manufactured homes and recreational vehicles (RVs), this product is also utilized in purling applications and for steel dunnage.

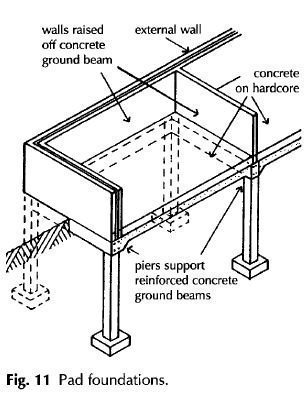

Beams are structural elements that transfer loads imposed along their length to their end points where the loads are transferred to walls, columns, foundations, and so on. An I-beam is made by rolling or milling steel which means the I-beam is often limited by the capacity or size of the milling equipment. I-beams have top and bottom flanges, and they are shorter and are not as wide as H-beams.

You can purchase structural beams from lumber yards, steel manufacturers, or big box retailers. Costs to install a steel beam range from $1,150 to $4,600, but will vary based on the size and type of steel beam you choose and the labor needed to install it. The more popular and cost-effective option, laminated veneer lumber (LVL) beams, ranges in price from $55 to $400, not including installation. was suspended a vertical hollow iron cylinder, which could be moved into or out of a wire coil or solenoid joined as a shunt across the two carbon rods of the furnace.

Why is the I beam so strong?

Channel question but in general a channel is one half of an I beam that is split down the vertical rib so yes, the I beam is stronger. But it also depends on the weight per foot, the flange width, and the thickness of the flanges.

A thin walled beam is a very useful type of beam (structure). The cross section of thin walled beams is made up from thin panels connected among themselves to create closed or open cross sections of a beam (structure). Typical closed sections include round, square, and rectangular tubes.

In actual means beams are the structural materials, which bear the bending moment and the shear force of the load. To carry on the more load and tension, pre-stressed concrete beams are widely used nowadays in foundation of bridges and other such humongous structures. Several famous beams used nowadays are Simply supported Beam, Fixed Beam, Cantilever Beam, Continuous Beam, Overhanging Beam. Aluminum rods can be as much as 25-percent lighter than steel rods, making them a popular choice with racers.

Again, the right choice for you will depend on the variables (power, rpm, application, etc.) above. H-beam connecting rods incorporate two large, flat sides with a thin section in the middle. This design makes these rods more rigid and able to handle compression forces.