$ 0.000 -0.02%

Bolt (BOLT) Rank 5553

| Mkt.Cap | $ 28,636.00 | Volume 24H | 0.00000000BOLT |

| Market share | 0% | Total Supply | 0.00000000BOLT |

| Proof type | N/A | Open | $ 0.0001 |

| Low | $ 0.0001 | High | $ 0.0001 |

Wheel bolt sizes

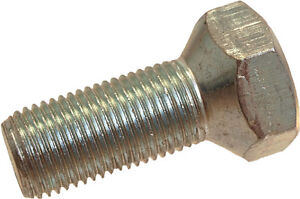

Therefore, a 1.5 pitch would have 1.5 millimeters between each thread. Fastener Type is the general type of fastener, such as wood screws, hex bolts, machine screws, hex nuts or carriage bolts. A machine screw is actually closer to a bolt than a screw. A machine screw threads into a nut or an insert, but unlike a bolt, it is meant to be tighted by the head of the machine screw. Thread pitch is measured as the distance between threads on a metric bolt.

A hexagon bolt comprises a head that has six sides, with threading that begins part-way down the shank, whereas a tap bolt’s shank is threaded the whole length. This type of bolt comprises two threaded ends instead of having a head, one of which contains a wood screw. A bolt is a type of fastener, usually made from metal, that commonly comprises a head at one end, a chamfer at the other, and a shaft characterised by an external helical ridge known as a ‘thread’. Bolts are typically used to hold materials or objects together, or to position objects.

T-head bolt

In the US, a different standard was developed, based on the size of the body of the bolt. In mainland Europe, a third system was developed based on the body size of the bolt using metric measurement.

This determines the durability of the bolt when subjected to repeated tension loads. Maintaining a sufficient joint preload also prevents relative slippage of the joint components that would produce fretting wear that could result in a fatigue failure of those parts. The preload achieved by torquing a bolt is caused by the part of the torque that is effective. Friction in the threads and under the nut or bolt head use up some fraction of the applied torque. Much of the torque applied is lost overcoming friction under the torqued bolt head or nut (50%) and in the threads (40%).

More accurate methods for determining the preload rely on defining or measuring the screw extension from the nut. This can be achieved using a dial test indicator, reading deflection at the fastener tail, using a strain gauge, or ultrasonic length measurement. Bolted joints are one of the most common elements in construction and machine design. They consist of fasteners that capture and join other parts, and are secured with the mating of screw threads.

What does 8.8 mean on a bolt?

Screws are typically used for securing mating parts. For examples, the clearance hole for a M3 screw has 3.2 mm or 3.5 mm diameter. the clearance hole for a M4 screw has 4.2 mm or 4.5 of diameter. And we would make a hole with 5.5 mm of diameter for a M5 screw.

Higher grade materials, such as carbon alloy steel, allow for greater torque strength in the threads of the bolt. The preload, or thread tension in a fastener is higher when the type of steel being used is grade 8 in quality. Bolts often rely on axial force causing sufficient friction at the threads to remain in place. A torque is applied to the head to generate this axial force.

Bolt heads

It is important that the threads cut into the bolt match the threads cut into the nut or part to be connected. Before the Industrial Revolution, each mechanic would cut his own threads into each part.

If one has a larger bearing area or coefficient of friction it will require more torque to provide the same target preload.[5] Fasteners should only be torqued if they are fitted in clearance holes. To achieve the benefits of the preloading, the clamping force must be higher than the joint separation load.

Metric bolts have numbers, standard bolts have little lines, and rusty bolts… good luck.Tensile strength is is the maximum amount of stress a bolt can endure from being stretched or pulled until it fails. Again this is only important when it comes to the application. Low grade bolts are going to work for most everyday applications, like mounting a flat screen television, or keeping your chair together.

Head

How do you cut a nut in half?

M10 means a 10 millimeter outer diameter for the bolt or whatever piece it is; M12 means 12 millimeters. The part after the 'x' is the pitch -- how many mm a thread is wide. To figure out which you have, you can measure the existing part with calipers and a thread gauge.

Anchor bolt - Bolt designed to allow objects to be attached to concrete. The bolt head is usually placed in concrete before it has cured, leaving the threaded end exposed. To simplify metric thread callouts, the international (ISO) standard for metric threads eliminates the pitch callout on coarse threads.

It is a good idea to keep both metric and SAE sockets in your car regardless of what type of bolts are used. A 12mm socket is just slightly smaller than a 1/2”, so you can tap it on with a hammer, add some lube and you might be home free.

A bolt is a mechanical fastener with a threaded shaft. Bolts are closely related to screws, which are also mechanical fasteners with threaded shafts.

Allow nuts to be attached to what is really a screw. Many screws use a screwdriver head fitting, rather than an external wrench.

Flange bolt

- Bolt extractors have a bad habit of breaking in the bolt, so be careful if you decide to use one.

- In a well designed joint, perhaps 80-90% of the externally applied tension load will pass through the joint and the remainder through the bolt.

- Cap nuts, also known as 'acorn nuts', are also similar to hex nuts, but they have a solid top to cover the exposed threads of the bolt.

- For example, the thread "M10" automatically means a coarse pitch, while any added pitch callout, such as M10x1.25, specifies a non-coarse pitch.

- There is no (as yet) simple method to measure the tension of a fastener in situ.

- It is a good idea to keep both metric and SAE sockets in your car regardless of what type of bolts are used.

For example, a 3/8-16 (coarse) thread has a 3/8" nominal major diameter and 16 threads per inch, while a 3/8-24 (fine) thread has the same nominal major diameter and 24 threads per inch. 2A spiral groove cut into the surface of a nut, bolt or screw. Flat-head bolts, as the name implies, have a flat top and angled bottom of the head allowing the bolt head to be flush with the surface of the part.

How can you tell if a bolt is metric?

SAE J429 (Society of Automotive Engineers) bolts have radial lines, whereas ASTM (American Society for Testing and Materials) uses a combination of letters and numbers to indicate the grade. Three radial lines will indicate an SAE grade 5 fastener, while six radial lines will indicate an SAE grade 8 fastener.

Such machines are often used to fit and tighten wheel nuts on an assembly line, and have also been developed for use in mobile plant tire fitting bays on mine sites. Another method that indicates tension (mainly in erecting steel) involves the use of crush-washers. These are washers that have been drilled and filled with orange RTV. When an given amount of force has been applied (± 10%), the orange rubber strands appear.

Material and Type

The joint should be designed such that the clamp load is never overcome by the external tension forces acting to separate the joint. If the external tension forces overcome the clamp load (bolt preload) the clamped joint components will separate, allowing relative motion of the components. Machine Screw Threads - used on bolts, setscrews, machine screws and designed to mate with preformed threads in nuts or tapped holes. Hanger bolt - Bolt that has no head, machine threaded body followed by a wood threaded screw tip.

What does m10x1 5 mean?

M14x1.5 means the threaded part is 14mm diameter, 1.5 is the pitch of the thread ie the distance between thread peaks.

The times you spend waiting will save you in the long run. Another lubrication trick is to heat the bolt up and then melt wax onto it. The heat wicks the wax into the threads and many times, the bolts will come right out.

The first two are 1/4″ diameter and the last one is 6mm. As you can see, the thread pitch of the coarse metric bolt is much finer than a coarse thread standard bolt. It’s hard to tell, but the fine thread standard bolt is just slightly finer then a regular coarse thread metric bolt. The following tables show the thread pitch of coarse and fine thread metric and standard bolts.

M14x1.5 means the threaded part is 14mm diameter, 1.5 is the pitch of the thread ie the distance between thread peaks. Since Carr Lane does business all across the world, we follow the international (ISO) standard for metric thread callouts. Stating the pitch of a metric coarse thread would be incorrect and totally confusing everywhere else in the world.

What is a bolt in engineering?

A bolt is a mechanical fastener with a threaded shaft. Bolts are closely related to screws, which are also mechanical fasteners with threaded shafts. These types of fasteners are typically inserted through two parts, with aligned holes.

Exceptions may be self piercing screws such as needle points or self-drilling screws like Type 17's which create their own hole; some Teksmay also have spaced threads. Spaced Threads - used on woodscrews, self-tapping screws, coach screws and Type 25 thread cutters. Designed to form its own thread, usually in a pre-drilled hole. In general, Steel is the most commonly used material of all fasteners (90%) or more.

Hex bolt head with thread screw tip for use in wood. Only the non curved section is threaded for a nut to be attached.

A prevalent test for the self-loosening behaviour is the Junker test. Overtorquing might cause failure by damaging the threads and deforming the fastener, though this can happen over a very long time. Undertorquing can cause failures by allowing a joint to come loose, and it may also allow the joint to flex and thus fail under fatigue.

For example, the thread "M10" automatically means a coarse pitch, while any added pitch callout, such as M10x1.25, specifies a non-coarse pitch. This method of designation has the major benefit that average citizens do not need to memorize pitches just to identify a coarse thread. Metric thread callouts are fundamentally different because the thread pitch (distance between each thread, in mm) is specified instead of threads per inch or per mm. For example, an M10x1.5 (coarse) thread has a 1.5mm pitch, while an M10x1.25 (fine) thread has a 1.25mm pitch.

Other such shear joints do not employ a preload on the bolt as they are designed to allow rotation of the joint about the bolt, but use other methods of maintaining bolt/joint integrity. Joints that allow rotation include clevis linkages, and rely on a locking mechanism (like lock washers, thread adhesives, and lock nuts). Grade 8 bolts are comprised of carbon alloy steel, thus giving them a high psi rating.

For bonus points here, you will notice these bolts aren’t made from the same materials. The two on the right are stainless steel, while the one on the left is zinc plated. Something very similar to pitch (but definitely not the same as) is what is called lead (pronounced like “leed”). This is the distance the bolt covers after one complete turn.