$ 0.000 %

Engine (EGCC) Rank 14522

| Mkt.Cap | $ 0.00000000 | Volume 24H | 0.00000000EGCC |

| Market share | 0% | Total Supply | 0.00000000EGCC |

| Proof type | N/A | Open | $ 0.00000000 |

| Low | $ 0.00000000 | High | $ 0.00000000 |

Engine Design & Classification: How automotive engines are categorized?

Which of the following is NOT one of the four cycles of an internal combustion engine?

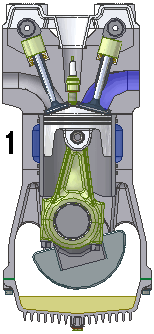

Also, the space consumed by the cylinders is quite compact as compared to other engines. The intake and exhaust valves open at the proper time to let in air and fuel and to let out exhaust. Note that both valves are closed during compression and combustion so that the combustion chamber is sealed.

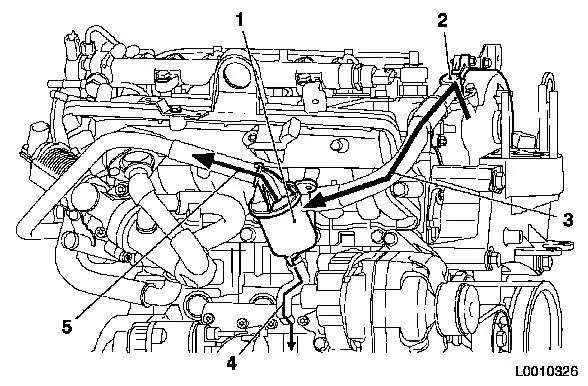

Autogas engines use either fuel injection systems or open- or closed-loop carburetors. Animated cut through diagram of a typical fuel injector, a device used to deliver fuel to the internal combustion engine. Radial aircraft engines had from three to 28 cylinders; examples include the small Kinner B-5 and the large Pratt & Whitney R-4360. As each row contains an odd number of cylinders, to give an even firing sequence for a four-stroke engine, an even number indicates a two- or four-row engine.

But no matter the engine, as long as it's of the internal-combustion variety, the basics of how it works remain the same. In today's most modern engines, gasoline is injected directly into the cylinders near the top of the compression stroke. (Other engines premix the air and fuel during the intake stroke.) In either case, just before the piston reaches the top of its travel, known as top dead center, spark plugs ignite the air and fuel mixture. In this article we will learn about different types of engine. So let’s discuss about different engine types one by one.

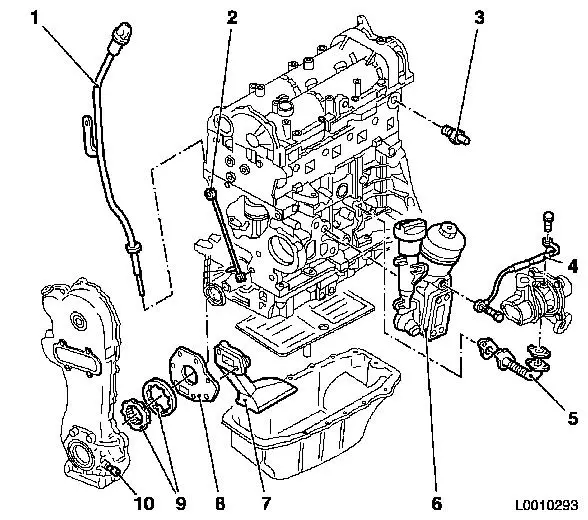

Heat shielding systems

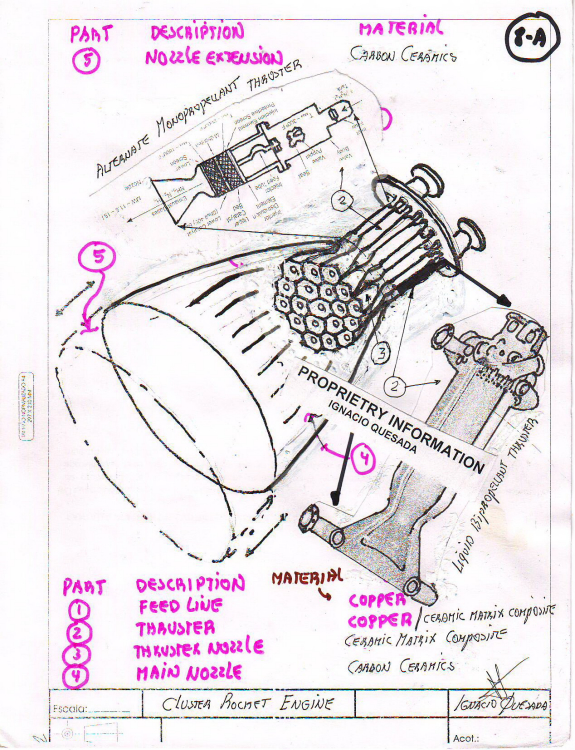

In the 13th century, the solid rocket motor was invented in China. Driven by gunpowder, this simplest form of internal combustion engine was unable to deliver sustained power, but was useful for propelling weaponry at high speeds towards enemies in battle and for fireworks.

Medium-size motors of highly standardized dimensions and characteristics provide convenient mechanical power for industrial uses. The very largest electric motors are used for propulsion of large ships, and for such purposes as pipeline compressors, with ratings in the thousands of kilowatts.

Most vehicle manufacturers began including PCMs during the 1980s, and the computer system has become standardized over the years. An engine block - also known as a cylinder block - contains all of the major components where the combustion process takes place in a reciprocating engine. In this engine construction, the engine has three rows of cylinders placed at an angle.

Toyota Vehicles with V6 Engines

Different configurations have different advantages and disadvantages in terms of smoothness, manufacturing cost and shape characteristics. These advantages and disadvantages make them more suitable for certain vehicles. Go take a look under your car’s hood today and see if you can point out the parts that we discussed. If you’d like some more info on how a car works, check out the book How Cars Work.

How Car Engine Works

The downward stroke that occurs directly after the air-fuel mix passes from the carburetor or fuel injector to the cylinder (where it is ignited) is also known as a power stroke. A four-stroke cycle engine is an internal combustion engine that utilizes four distinct piston strokes (intake, compression, power, and exhaust) to complete one operating cycle. The piston make two complete passes in the cylinder to complete one operating cycle. An operating cycle requires two revolutions (720°) of the crankshaft.

Electric motors are ubiquitous, being found in applications as diverse as industrial fans, blowers and pumps, machine tools, household appliances, power tools, and disk drives. They may be powered by direct current (for example a battery powered portable device or motor vehicle), or by alternating current from a central electrical distribution grid. The smallest motors may be found in electric wristwatches.

The engine block is also referred to as the cylinder block because of the big hole or tubes called cylinders that are cast into the integrated structure. The cylinder is where the engine’s pistons slide up and down. The more cylinders an engine has the more powerful it is. In addition to the cylinders, other ducts and passageways are built into the block that allow for oil and coolant to flow to different parts of the engine.

The increased droplet surface area exposed to the ignition flame allows more complete burning of the charge in the combustion chamber. An increase in droplet surface area allows gasoline to release more vapor rather than remaining a liquid.

The first piston engines did not have compression, but ran on an air-fuel mixture sucked or blown in during the first part of the intake stroke. The most significant distinction between modern internal combustion engines and the early designs is the use of compression of the fuel charge prior to combustion.

There are small, rounded indentations cast into the cylinder head in order to create room at the top of the chamber for combustion. A head gasket seals the joint between the cylinder head and cylinder block. Intake and outtake valves, spark plugs, and fuel injectors (these parts are explained later) are also mounted to the cylinder head.

Other internal combustion engines like jet engines and rocket engines employ various methods of fuel delivery including impinging jets, gas/liquid shear, preburners and others. Simpler reciprocating engines continue to use a carburetor to supply fuel into the cylinder. Although carburetor technology in automobiles reached a very high degree of sophistication and precision, from the mid-1980s it lost out on cost and flexibility to fuel injection. Simple forms of carburetor remain in widespread use in small engines such as lawn mowers and more sophisticated forms are still used in small motorcycles.

How does a car run?

Fuel rack adjusts the position of the fuel pump plunger which in turns determines the amount of fuel going to the cylinder. Angle of the plunger helix adjusted by the rack determines amount of fuel to be injected. Thus governor adjusts fuel pump linkages into position to add more fuel into the cylinder.

The spark must happen at just the right moment for things to work properly. So that inline four we mentioned at the beginning is an engine with four cylinders arranged in a line.

- Horsepower output ranges slightly between specific models, though access to between 295 and 301 horsepower from the Avalon and Camry V6 engines gives drivers about 100 more horsepower than comparable four-cylinder models.

- In this engine construction, the engine has three rows of cylinders placed at an angle.

- And thanks to the turbo-like boost from the electrics, the car never seems to run short of passing power.

- In this article we will learn about different types of engine.

- Electric motors convert electrical energy into mechanical motion, pneumatic motors use compressed air, and clockwork motors in wind-up toys use elastic energy.

Four cylinders and power ratings from 19 to 120 hp (14 to 90 kW) were followed in a majority of the models. Several three-cylinder, two-stroke-cycle models were built while most engines had straight or in-line cylinders. There were several V-type models and horizontally opposed two- and four-cylinder makes too. The smaller engines were commonly air-cooled and located at the rear of the vehicle; compression ratios were relatively low.

Long history of the car

Is a 2.0 liter engine fast?

2.5 L. The Duratec 25 is a 2.5 L (2544 cc) 60° V6 and was introduced in 1994. It was developed for the Ford Contour and also used in the Ford Mondeo and others. Bore and stroke is 82.4 mm × 79.5 mm (3.24 in × 3.13 in).

As the air/fuel mixture burns it expands rapidly causing the pressure inside the cylinder to increase. This increase in pressure forces the pistons down the cylinder thereby driving the connecting rod to turn crankshaft providing us with a continuous rotating motion with which to drive the vehicle and other components. This engine has a mass of 2,300 tonnes, and when running at 102 RPM (1.7 Hz) produces over 80 MW, and can use up to 250 tonnes of fuel per day. In 1877 the Otto cycle was capable of giving a far higher power to weight ratio than steam engines and worked much better for many transportation applications such as cars and aircraft.

Fuel can stick to deposits on the intake valve and not enter the combustion chamber when needed. The right fuel additive can help reverse these effects and restore lost performance. The fuel injector is the last stop for fuel in your engine before it goes "boom!" inside the combustion chamber. It is basically an electrically operated gate that opens just long enough to meter the perfect amount of fuel to run the engine.

What is the first engine?

Search engine is a service that allows Internet users to search for content via the World Wide Web (WWW). A user enters keywords or key phrases into a search engine and receives a list of Web content results in the form of websites, images, videos or other online data.

The crankshaft is what converts the up and down motion of the pistons into a rotational motion that allows the car to move. The crankshaft typically fits lengthwise in the engine block near the bottom. It extends from one end of the engine block to the other.

All four-stroke internal combustion engines employ valves to control the admittance of fuel and air into the combustion chamber. Two-stroke engines use ports in the cylinder bore, covered and uncovered by the piston, though there have been variations such as exhaust valves. Devices converting heat energy into motion are commonly referred to simply as engines.[3] Examples of engines which exert a torque include the familiar automobile gasoline and diesel engines, as well as turboshafts. Examples of engines which produce thrust include turbofans and rockets. An engine or motor is a machine designed to convert one form of energy into mechanical energy.[1][2] Heat engines, like the internal combustion engine, burn a fuel to create heat which is then used to do work.

In 1864, Nikolaus Otto patented the first atmospheric gas engine. In 1872, American George Brayton invented the first commercial liquid-fueled internal combustion engine.

What is fuel rack?

An engine block - also known as a cylinder block - contains all of the major components where the combustion process takes place in a reciprocating engine. Usually made from an aluminium alloy (cast iron in older engines), it houses the cylinders and their components, the water cooling system and the crankcase.

The four phases of operation (intake, compression, power, and exhaust) take place in what is effectively a moving, variable-volume chamber. Turbochargers are another type of forced induction system which has its compressor powered by a gas turbine running off the exhaust gases from the engine. A supercharger is a "forced induction" system which uses a compressor powered by the shaft of the engine which forces air through the valves of the engine to achieve higher flow. When these systems are employed the maximum absolute pressure at the inlet valve is typically around 2 times atmospheric pressure or more.

Linear motion can come from either a diaphragm or piston actuator, while rotary motion is supplied by either a vane type air motor or piston air motor. Pneumatic motors have found widespread success in the hand-held tool industry and continual attempts are being made to expand their use to the transportation industry. However, pneumatic motors must overcome efficiency deficiencies before being seen as a viable option in the transportation industry.

2. Internal Combustion Engine or I.C. Engine

Prior to the 20th century, the burning or combustion of the fuel took place outside of the actual engine. The steam was held under pressure and then introduced into the engine where it forced the piston down in the cylinder. This is referred to as an External Combustion Engine or traditionally called a steam engine. When the internal combustion engine was invented, the term motor was initially used to distinguish it from the steam engine—which was in wide use at the time, powering locomotives and other vehicles such as steam rollers. The term motor derives from the Latin verb moto which means to set in motion, or maintain motion.

Pre-industrial weapons of war, such as catapults, trebuchets and battering rams, were called siege engines, and knowledge of how to construct them was often treated as a military secret. Most mechanical devices invented during the industrial revolution were described as engines—the steam engine being a notable example. However, the original steam engines, such as those by Thomas Savery, were not mechanical engines but pumps. In this manner, a fire engine in its original form was merely a water pump, with the engine being transported to the fire by horses.