$ 0.000 %

Influence Chain (INFC) Rank 15035

| Mkt.Cap | $ 0.00000000 | Volume 24H | 0.00000000INFC |

| Market share | 0% | Total Supply | 0.00000000INFC |

| Proof type | N/A | Open | $ 0.00000000 |

| Low | $ 0.00000000 | High | $ 0.00000000 |

Influence of Chain Length and Unsaturation on Sphingomyelin Bilayers

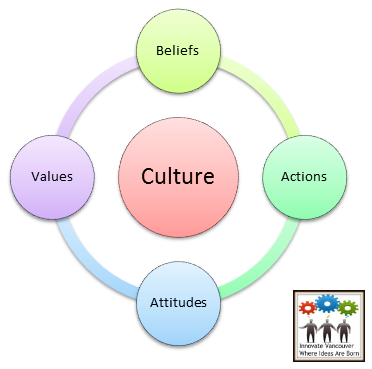

begin from the primary agricultural phase, proceed with manufacturing and retail, and end with household consumption. During this life cycle, food is lost or wasted because of technological, economic, and/or societal reasons. The definitions of “food waste” and “food loss” within the supply chain have been a subject of disagreement among the related scientists. At Samsung, we fully take on our responsibility in advancing human rights management along the entire supply chain, abide by international human rights agreements to guarantee workplace safety and comply with the code of conduct set by the Responsible Business Alliance (RBA). We regularly monitor all our suppliers in accordance with EICC’s verification standards to identify issues and make necessary improvements.

Prosecution will need to demonstrate to the court that a party in the chain of responsibility did not do all that was reasonably practicable to ensure the safety of the party’s transport activities. The law recognises that multiple parties may be responsible for offences committed by the drivers and operators of heavy vehicles.

Under COR laws if you are named as a party in the chain of responsibility and you exercise (or have the capability of exercising) control or influence over any transport task, you have a responsibility to ensure the HVNL is complied with. Inventory is used to decouple demand and supply, to buffer variability in demand and supply.

Trends in food supply chain management

Furthermore, we continuously support our suppliers to build mutual competitive edge and growth. We ensure that our suppliers build a stronger competitive edge through support and cooperation in order to establish a sound corporate ecosystem and a sustainable supply chain. It also allows the top management to communicate their message to the entire organisation and supervisors at each level become responsible to execute that order. A proper chain of command allows business to run smoothly but it also makes it inflexible at times.

Supply Chain 4.0 – the next-generation digital supply chain

Moreover, FAO distinguishes “food waste” as an important part of “food loss,” which refers to the removal of food from the supply chain, which fits for consumption by choice or has been left to spoil or expire as a result of negligence (predominantly but not exclusively) by the final consumer at household level. In order to secure food production to satisfy growing demand, while maintaining or recovering in the environmental front, will require a conscious effort to improve and optimize food supply chains in terms not only of economic and operational performance, but social and environmental ones. The use of organic and carbon foot-print eco-labels, social justice labels, and other means of informing consumers will need to become a means of internalizing many cost that have overwhelmingly been considered externalities to food companies. Sustainable consumption and public policy is and will be required to accelerate the rate of change.

In combination with smart automation and productivity improvement in warehousing, on-board units in transportation, etc., the savings potential can be achieved. The remaining 15 percent cost reduction can be reached by leveraging approaches of dynamic routing, Uberization of transport, leveraging autonomous vehicles, and - where possible - 3-D printing. Eliminating today's digital waste and adopting new technologies is a major lever to increase the operational effectiveness of supply chains.

Setting Your Browser to Accept Cookies

In addition to ensuring that production mechanics are seamless and efficient, it's critical that a business keep its customers feeling confident and secure enough to remain loyal. A company conducts a value-chain analysis by evaluating the detailed procedures involved in each step of its business. The purpose of a value-chain analysis is to increase production efficiency so that a company can deliver maximum value for the least possible cost.

By implementing new planning algorithms, the uncertainty (the standard deviation of the demand/supply or forecast error) will be reduced significantly, making safety stock unnecessary. The other important variable to drive inventory is the replenishment lead time - with more production of Lot Size 1 and fast changeover, the lead time will be reduced significantly.

Several technologies have emerged that are altering traditional ways of working. On top of this, mega trends and customer expectations change the game. Besides the need to adapt, supply chains also have the opportunity to reach the next horizon of operational effectiveness, to leverage emerging digital supply chain business models, and to transform the company into a digital supply chain. Qualitative loss refers to the decrease in edible food mass throughout the part of the supply chain that specifically leads to edible food for human consumption.

Supply Chain 2.0 characterizes "mainly paper-based" supply chains with a low level of digitization. The digital capabilities of the organization are very limited and available data is not leveraged to improve business decisions.

The "incubator" is the seed of Supply Chain 4.0 in the organization - fast, flexible, and efficient. Low customer service is either driven by a wrong promise to the customer (e.g., unrealistic lead times), a wrong inventory profile (ordered products are not available), and/or an unreliable delivery of parts. Lost sales in addition occur if the required products are not available on the shelf or in the system - customers will decide to switch to another brand. Whereas in the past, the generation of KPI dashboards was a major task and KPIs were only available at aggregated levels, now granular data is available in real time from internal and external sources. This moves the performance management process from a regular, often monthly process to an operational process aimed at exception handling and continuous improvement.

Samsung Electronics and our suppliers are responsible for the sustainable satisfaction of our customers and civil society. Also, we promise to take full responsibility of the supply chain based on trust and sincerity for the best value. Real-time replanning enables order date confirmations through instantaneous, in-memory replanning of the production schedule and the replenishment in consideration of all constraints. Therefore the supply chain setup is always up to date, leading to a very reliable planning base. On top, additional services can be offered to the customers, e.g., a faster lead time for a certain premium fee, so the customer can see the feasibility and the updated dates at a glance.

Blockchain Guides

Another example in warehousing is advanced shipping notifications, which are received but not used to optimize the inbound process. The demand of customers for more and more individualized products is continuously increasing. That gives a strong push towards microsegmentation, and mass customization ideas will finally be implemented. Customers are managed in much more granular clusters and a broad spectrum of suited products will be offered. This enables customers to select one of multiple "logistics menus" that exactly fits their need.

- Hopefully overpassing the rate at which climate change is depleting the natural landscape form which food is produced, and the rate at which food shortage is becoming more pressing as demographics and world economics continuously evolve.

- Capabilities regarding digitization need to be built in the organization (see the chapter on capability building) but typically also require targeted recruiting of specialist profiles.

- In order to secure food production to satisfy growing demand, while maintaining or recovering in the environmental front, will require a conscious effort to improve and optimize food supply chains in terms not only of economic and operational performance, but social and environmental ones.

- These systems allow economic analyses and benchmarking against competitors but also support the quality-related data exchange required by government and private regulation.

- In the future we will see "predictive shipping," for which Amazon holds a patent - products are shipped before the customer places an order.

- Customers are managed in much more granular clusters and a broad spectrum of suited products will be offered.

Samsung Electronics ban the use of conflict minerals – including tantalum, tin, tungsten and gold – that are mined unethically in conflict areas in 10 African locations, including Democratic Republic of the Congo (DR Congo). We manage our supply chain based on the principle of an ethical distribution process. To ensure our suppliers to be held to the highest standards, we conduct thorough examinations on the minerals used in their products. To establish a conflict-free system, we have implemented a process of due diligence for conflict minerals in line with the ‘OECD Due Diligence Guidance’. The transformation into a digital supply chain requires two key enablers - capabilities and environment.

A person may be a party in the supply chain in more than one way. For example they may have duties as the employer, the operator and the consigner of goods. The aim of COR is to make sure everyone in the supply chain shares responsibility for ensuring breaches of the HVNL do not occur.

Influence Chain 24h Vol $407

These new technologies enable a significant improvement of demand forecast accuracy, often reducing the forecasting error by 30 to 50 percent. Also, the days of a "single truth" regarding the forecasting numbers are over - these advanced algorithms provide probability distributions of the expected demand volume rather than a single forecast number.

Components of a Value Chain

) but, owing to agency problems, cannot always be taken for granted. Therefore, recent government (food laws) and private (certification schemes) regulation has more intensively focused on the quality-related information stored and transmitted in food supply chains. Although parts of the regulatory framework apply to all agricultural and food products, the main focus is on meat production which is highly susceptible to food safety incidents.

The performance management system is able to identify the root causes of an exception by either comparing it to a predefined set of underlying indicators or by conducting big data analyses, leveraging data mining and machine learning techniques. Based on the identified root cause, the system will automatically trigger countermeasures, such as activating a replenishment order or changing parameter settings in the planning systems, such as safety stocks.

This range of data provides a joint information basis for all levels of seniority and functions in the supply chain. The integration of data of suppliers, service providers, etc. in a "supply chain cloud" ensures that all stakeholders steer and decide based on the same facts. ) global voluntary definitional framework defined “food loss” as the decrease in quantity or quality of food, caused mainly by food production and supply system functioning or its institutional and legal framework. Thereby, “food loss” occurs throughout the food supply chain. global voluntary definitional framework defined “food loss” as the decrease in quantity or quality of food, caused mainly by food production and supply system functioning or its institutional and legal framework.

The next generation of performance management systems provides real-time, end-to-end transparency throughout the supply chain. The span of information reaches from synthesized top-level KPIs, such as overall service level, to very granular process data, such as the exact position of trucks in the network.

Hopefully overpassing the rate at which climate change is depleting the natural landscape form which food is produced, and the rate at which food shortage is becoming more pressing as demographics and world economics continuously evolve. Food supply chains are complex networks consisting of small- and medium-sized enterprises (ie, farms, departments of processing companies) that interact with multinational companies providing input to the supply chain and doing its retail. Following the need for further individualization and customization of the supply chain, supply chain setups adopt many more segments.

Many companies have started to implement an integrated planning process, but very often this is still done in silos and not all information is leveraged to achieve the best planning result possible. In addition, it can frequently be observed that automatically determined planning or statistical forecast data is manually overwritten by planners.

Systems such as Desk-x or Farmer’s Friend represent standard software solutions to communication problems in food supply chains. These systems allow economic analyses and benchmarking against competitors but also support the quality-related data exchange required by government and private regulation. The diagnostic tool assesses the supply chain systematically based on six value drivers and five assessment dimensions (e.g., data, analytics). It differentiates between three archetypes of maturity levels.

If the worst comes to the worst, the issue will cause trouble in the assembly line replenishment and operational problems. In digital performance management systems, clean-sheet models for warehousing, transport, or inventory are used to set targets automatically.

By now, the first production facilities that operate exclusively with 3-D printers have been established. New business models, such as Supply Chain as a Service for supply chain planning functions or transport management, increase the flexibility in the supply chain organization. Supply chain can be bought as a service and paid for on a by-usage basis instead of having the resources and capabilities in-house. The specialization and focus of service providers allow them to create economies of scale as well as economies of scope and also attractive outsourcing opportunities. Supply chain management is the management of the flow of goods and services as well as overseeing the processes that convert original materials into final products.